Welcome to

Jet industries

Welcome to Jet Industries (Thailand)

40+ Years of Production Excellence

At Jet Industries, we believe in an efficient, responsive and innovative collaboration with our clients. Our service team strive to provide the best in class services with top-notch qualities.

At JET..

We strive to provide customers with best in class service through highly precise equipments and strict production procedures. These elements ensures that our products are of highest quality and precision. Advanced technology, timely service, expert personnel, corporate culture are all part of Jet Industries core values.

Our services

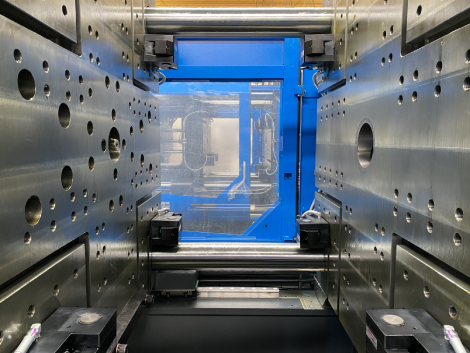

Precision Injection Molding

40+ years of precise thermoplastic injection moulding application in consumre electronics, household appliances and automotive industries in single / double color injection molding.

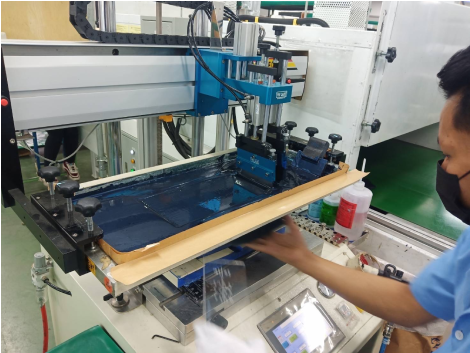

Secondary Processing

Part secondary processes include: spray painting, silk screening, pad printing, ultrasonic welding, hot stamping, laser marking, sub assembly.

Tool Fabrication

In-house tooling factory allows production of tools for machine range from 40 - 1600 tonnes. We are able to design, discuss, trial test, make maintenance and produce molds as per customer's requirements.

Our services process

1. Product onboarding

This process step involves gathering requirements and specifications, prototyping, and testing to ensure that the injection molded product is fit for purpose. The engineering team then works with the customer to design the right tooling and system to produce the desired product.

2. Trial and sampling

Once the product is designed and constructed, it is tested in a production trial run to ensure it meets all requirements. If a product passes all tests, it is then made available for sampling. The sampling process allows customers to confirm that the injection molded product meets their expectations and ensures it is ready for mass production.

3. Mass production

This step involves manufacturing the injection molded parts in volume using the injection molding process. The entire production process is tracked and monitored to ensure that the parts consistently meet the desired specifications.

4. Quality assurance

Quality assurance ensures that the parts manufactured are of the highest quality and meet all customer requirements. This step involves a thorough inspection of the injection molded parts to ensure they meet the required specifications.

5. Delivery

Once the parts pass the quality assurance process, they are then packaged and shipped to the customer according to their requirements.

6. Mold maintenance

The final step in the injection molding process is mold maintenance. This involves regularly inspecting and maintaining the tooling and system to ensure that it continues to produce quality parts. This includes cleaning, repairing, and replacing components as necessary.

Product range and beyond

Our Products

Our Products

News and updates

March 27, 2025

JET Helps Samut Sakhon Hospital

In a continued effort to support the local healthcare system, Jet Industries has made a meaningful contribution to Samut Sakhon Hospital by donating two electric-powered hospital beds, valued at 260,000 Thai Baht. The donation was made in 2024 as part of the company’s commitment to corporate social responsibility and community well-being. These advanced electric hospital…

February 7, 2024

Up and running: New Phase, New Factory

The completion of Jet Industries’ new factory spaces in 2023 marks a significant milestone in our growth and operational expansion. These newly constructed facilities are designed to meet the evolving demands of the injection molding industry, enabling us to increase our production capacity, improve workflow efficiency, and better serve our customers across various sectors. With…

June 28, 2023

Solar and Green.

Jet Industries has recently implemented solar energy generation systems at both of its principal manufacturing facilities located in Chonburi and Samut Sakhon. This strategic initiative underscores our long-term commitment to environmental responsibility and supports the sustainability goals of our valued partners, while simultaneously enhancing our position within an increasingly environmentally conscious marketplace. Solar energy presents…

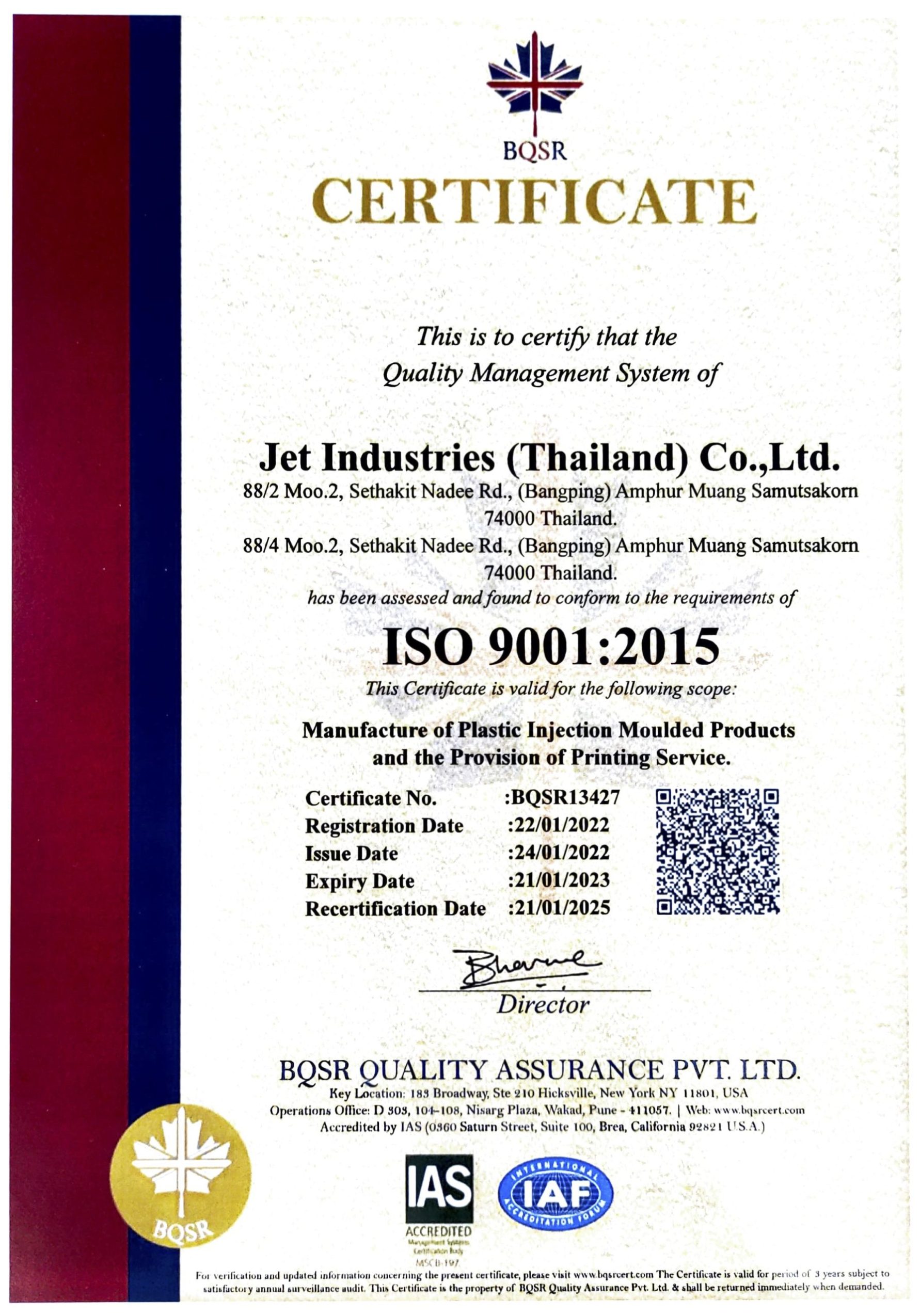

Lastest certificate